IOC-SCJ

When the overcentre valve is assembled at the bottom of the cylinder or near the cylinder, when the fluid line bursts and the pump hasn't been operated but the directional valve is started accidentally, the valve would start the loading and remain at the original position and then generate safe control.

The relief function of the overcentre valve can supply the losing of speed control or cavitation made by fluid protection which is needed by heat swelling.

Overcentre valves offer a standard control to avoid the speed of loading is bigger than the pump flow.

The design of check valve allows the fluid enter the cylinder free from port 2 to port 1.

In opposite, from port 1 to port 2, it must be higher than the setting pressure then the flow appears.

Or it's generated by the pilot pressure (port 3).

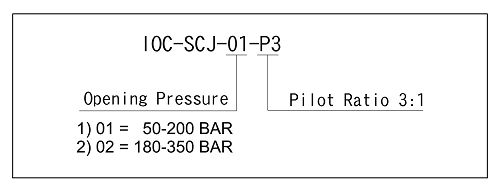

The pilot pressure of the valve must be [setting pressure -loading pressure] ÷ pilot ratio.

The setting pressure is normally 1.3 times than the max. loading pressure.

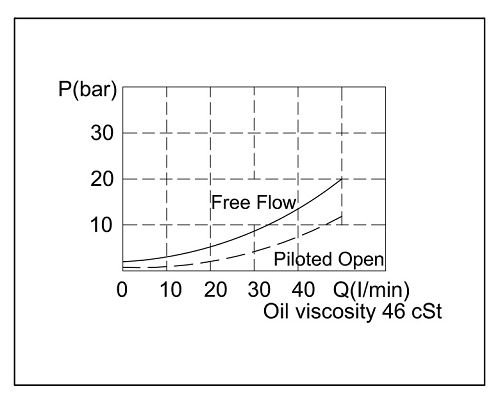

Rated Flow :

30 l/min

Max. pressure :

350 bar

Leakage :

0.3 ml/min (5 dpm)

Working temperature :

Min. -20℃ , Max. 90℃ , with standard BUNAN gaskets

Min. -20℃ , Max. 120℃ , with optional VITON gaskets on request

Fluid :

best use mineral oil with viscosity ranging between 10 and 200 cSt

Filter :

25 micron or better

Cavities :

see cavity data ST11A

Installation :

before screwing the cartridge on the valve body, ascertain to provide suitable gasket lubrication with clean oil and also be sure to screw the cartridge manually in to reach against the gaskets in the valve body.

.jpg)

.jpg)